We use these cookies to gather information about the way users interact with our website..We use this information to create reports and help us improve the website.

Read our Privacy Policy or Cookie Policy

AcceptTechnology & Installation

- Technology & Installation Method

- Direct Buried

- Directional Drilling

Direct Buried

HDD

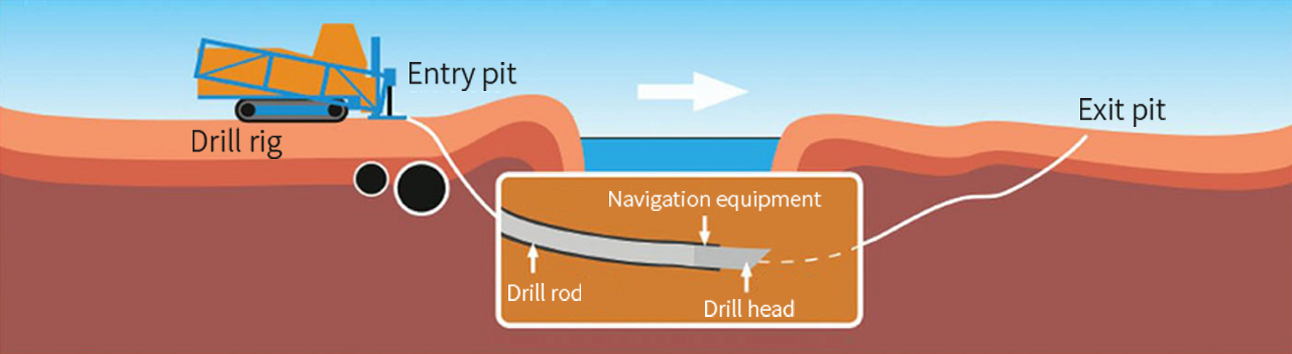

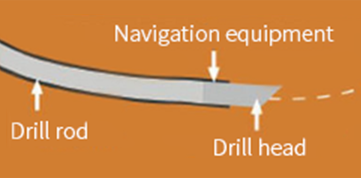

Horizontal boring is necessary when crossing a barrier where digging a trench is not an option such as an active roadway or a body of water. Without being able to view the duct’s path, it is necessary to perform a survey using ground penetrating radar to choose a path free of obstacles such as rocks or existing infrastructure.

The boring should take place with the drilling machine on one and, and a locator at the other end with a device able to track the head of the drill. A pilot hole is dug at both ends. Carefully navigate the drill head carefully through the desired path ensuring that the drill head does not strike any obstacles.

Before being pulled back through the hole using the swivel, the microduct must be properly attached. First, the bare end of the duct should be covered using an end sleeve or water tight shrink wrap. It is not recommended to use electrical tape for this purpose. Next a pulling grip is slid over the end of the microduct. The pulling grip is a woven cylinder, that when pulled backwards along the microduct, tightens and firmly grips the duct sheath (Think of a Chinese finger trap).

Once the drill head emerges, the locator should replace the drill head with a swivel. The swivel ensures that the microduct does not become twisted while being pulled back through the path. A reamer can also be used to widen the hole so that the duct does not become stuck.

The pulling grip should cover approximately three feet of the microduct end, with very little dead space between the end of the duct and the grip hook. Electrical tape should be used to secure the pulling grip to the duct sheath while the grip is tightened.

Now the duct is ready to be pulled back through the hole towards the machine. A safety rope should be attached to the swivel on the locator end in case the microduct and swivel become disconnected. The pulling grip puts a great deal of stress on the microduct near the pulling end. Therefore about six feet of duct should be cut and discarded (twice the length that the pulling grip covers).

KNET Microduct Assemblies has been rigorously tested by Telcordia Technologies and found to be compliant to Telcordia GR-3155-CORE.